SIP

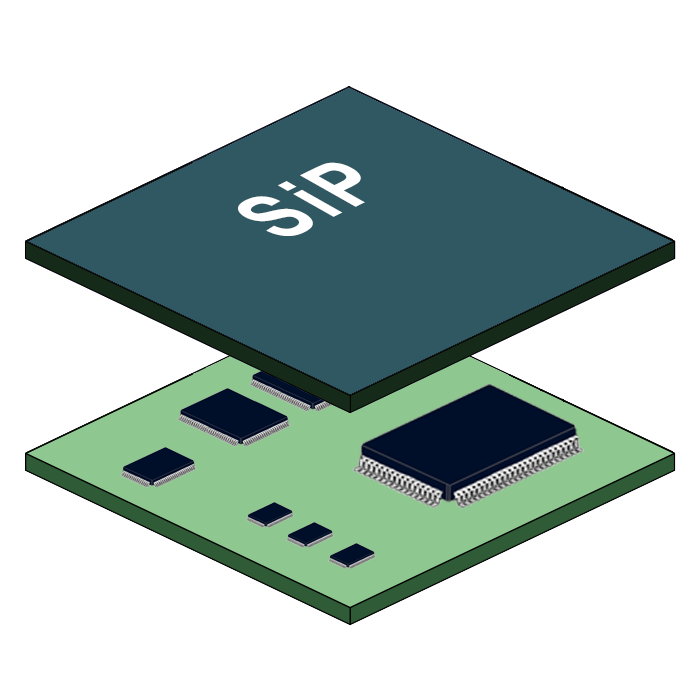

What is SiP?

SiP stands for System in Package.

SiP modules are fully functional subsystem that integrates one or more IC chips and passive components in a single package.

Advantages of SiP

-

Compact

SiP module integrates multiple chips together, which can save PCB space compared to individually packaged ICs that are of the same function.

-

Quick Turnaround Time

The SiP module itself is a system or subsystem that can be used in a larger system, and the debugging phase can be completed faster for QA and pre-qualification.

-

Simplifies System Design

SiP reduces the complexity of PCB circuit design by incorporating complex circuits into the modules, and SiP modules provide quick replacement capabilities, allowing system designers to easily add the desired functions.

-

Inseparability

SiP technology is inseparable from our life, such as mobile phones, computers, cameras, and so on. Not only that, its scope has been extended to medical electronics, automotive electronics, military, and aerospace. The Apple Watch, Google Glass, PillCam (capsule endoscope), etc. that the world has heard so much about have all benefited from the development of SiP technology.

-

High Production Efficiency

By integrating and separating passive components in SiP, the defect rate is reduced and the overall product yield is improved. The module adopts an advanced IC packaging process to reduce the system failure rate.

-

Simplifies System Testing

SiP modules are tested before shipment, reducing system testing time for the entire product unit.

-

Low Cost

Although SiP modules are more expensive than individual components, the reduced PCB space, low failure rate, low testing cost, and simplified system design can reduce the overall cost.

-

Simplifies Logistics Management

SiP modules can reduce the number of items and quantities of materials in the warehouse and simplify the production process.